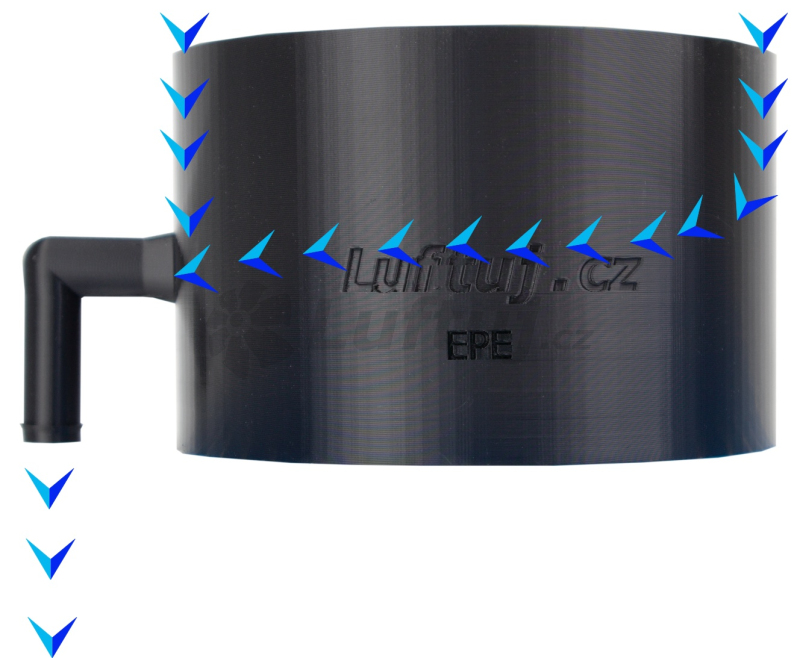

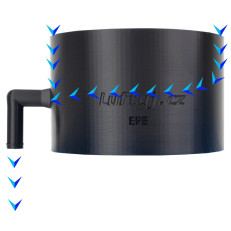

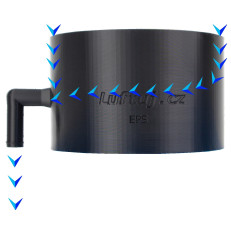

LUFTooL Trap - Condensing Piece for EPE Pipes

LUFTooL Trap products are designed to collect condensed water on the inside of the pipe in the ventilation systems. They are usually installed on pipes that blow air from the interior through the unheated part of the house. The condensation piece drains condensate from the duct walls outside the duct.

Our Condensing Pieces are:

• very tight - designed to save space compared to other condensate collection solutions

• equipped with a gutter elbow that is compatible with conventional condensate drainage hoses

• made of PETG material, thus minimising the formation of thermal bridges

• designed to be installed in vertical and horizontal pipes (horizontal pipes must always be in a gradient towards the drain)

• efficient, depending on the flow rate and type of pipe material, they are able to collect up to 91% of condensed moisture

• manufactured in three variants (for EPE, EPS and SPIRO pipes)

• which is a flexible and strong material

• has high impact resistance and durability

• is made from health-safe materials

• has low shrinkage on cooling

• is 100% recyclable

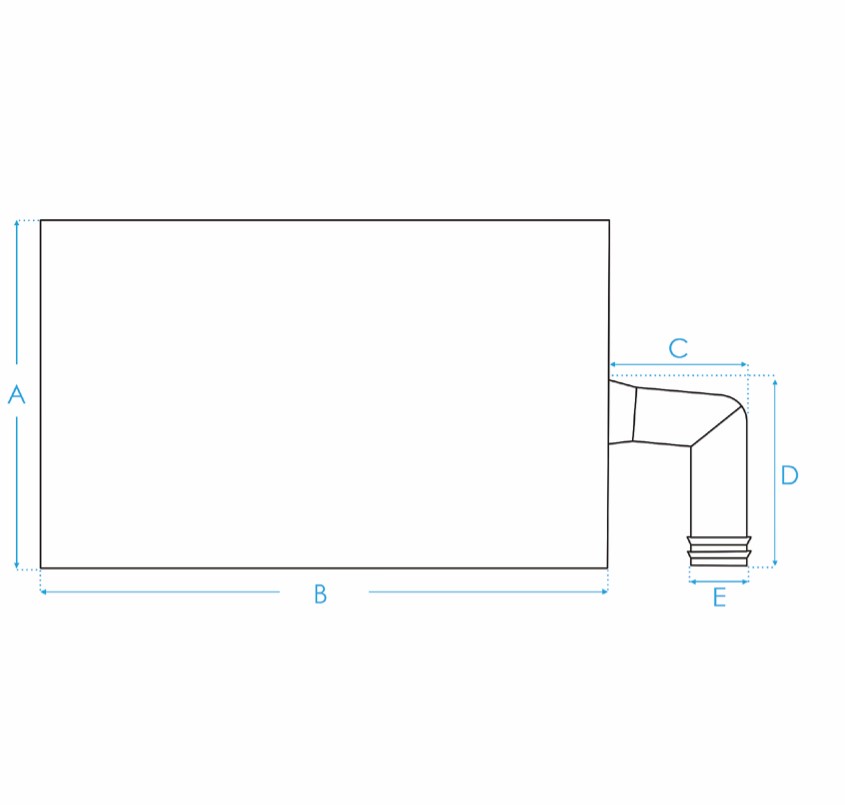

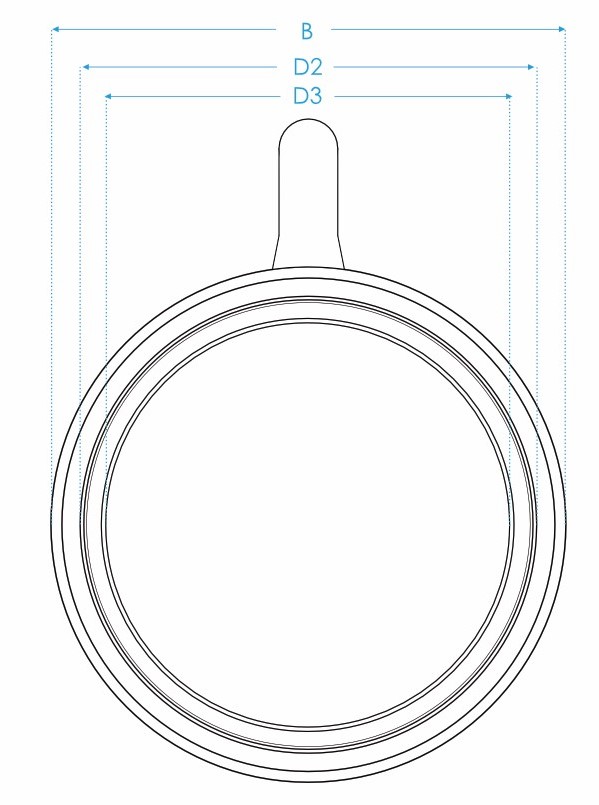

Cut the pipe in the place where you want to place the condensation piece. Vertical piping at the heated boundary of the thermal envelope is ideal.

Place a condensation piece on the bottom of the pipe and cut a hole for the plastic elbow as tightly as possible with a snap-off knife. Insert the condensation piece and fit the top parts of the pipe.

Seal the joint airtight with aluminum tape and thermally secure with at least two layers of thermal tape.

Connect the condensate drain hose to the elbow and connect it to the sewer through a flooded siphon (beware of freezing).

Condensation piece, manual. Packed in a box or foil.

Manual:

This product is made Luftuj LtD in the Czech Republic and exported to several European countries.

Accessories

You might be interested

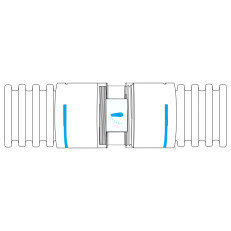

LUFtooL Damper set for Pipes Manual 90 mm

LUFTool Damper set – is a damper designed for installation on flexible plastic air ducting with an outer diameter of 90 mm. The damper is manually operated in seven positions. LUFTooL Distribute is: An innovative system for distributing airflow to individual zones/rooms. Designed for flexible plastic ducts with a diameter of 90 mm and traditional SPIRO ducting with a diameter of 100 mm. Intended for ventilation in residential homes and small businesses with airflow rates in individual branches up to 100 m³/h. Very tight, achieving a tightness class D according to ČSN EN 15727. Suitable for supplying and extracting normally polluted air (without chemicals, etc.). Fully cleanable, as brushes can be passed through the damper without disassembling the damper module. Made from ABS and PETG materials. LUFTool Damper set includes the following components of the Distribute system: LUFTooL Spigot for Ducting (90 mm, female) LUFTooL Damper module (manual control) LUFTooL Spigot for Ducting (90 mm, male) Damper Module available in manual:

Price on request

not in stock

LUFTooL Damper Module (manual)

The automatic damper module is part of the LUFTooL Distribute series. The damper enables automatic control and, together with other elements of the modular system, is used for zoning ventilation with heat recovery in family houses, apartments and small businesses. The system can be used for both supply and exhaust air with flow rates up to 100 m3/h in one branch. The LUFTooL Distribute system is: • an innovative system for distributing air flow into individual zones/rooms • modular (its components can be combined) • designed for flexible plastic pipes with a diameter of 75 and 90 mm and traditional SPIRO pipes of 100 mm • designed for ventilation in family houses and small businesses with air flows through individual branches up to 100 m3/h • a very tight system achieves tightness class D according to ČSN EN 15727 • suitable for the supply and exhaust of commonly polluted air (without chemicals, etc.) • fully cleanable, brushes can be pulled through the damper without dismantling the damper module • made of ABS and PETG The package contains: A plastic molding of the damper body (ABS) fitted with a damper blade and damper axis (PETG). A calibrated servo drive is mounted on the module body in the closed position. Instructions. Unlike the illustration, the package does not contain a blue cover. Packed in a plastic bag. The damper module can be screwed on one side, e.g. to: LUFTooL connectors (LF-CO-125) - which are inserted into the distribution box LUFTOMET® Flat boxes On the other hand, the module is ready for connection to LUFTooL pipe sockets: LT-SP-75-F....LUFTooL Spigot pipe socket (75 mm, female) LT-SP-90-F....LUFTooL Spigot pipe socket (90 mm, female) LT-SP-100-F....LUFTooL Spigot pipe socket (100 mm, female) (spout for traditional SPIRO pipes, white plastic or flexible SONO, Mastersan, etc. pipes, dimension 100 mm) Installation examples 1) installation via the connector to the distribution box - regulates the air flow coming out of the distribution box 2) installation in front of the LUFTOMET Flat box - regulates the air flow before the outlet Characteristics servo drive Operating voltage: 4.8 - 6.0 V Gear material: metal (first gear from the motor plastic) Dimensions: 23 x 12 x 29 mm Standing torque: 1.8 kg/cm (4.8 V); 2.2 kg/cm (6.0 V) Temperature range: 10 to +50°C Weight: 13.5 grams Wire length: 175 mm Rotation tolerance: ± 8% Controlling the damper module To control the damper module, you can purchase the LUFTaTOR API12 control module - this is software and a control board that allows you to control up to 12 dampers using the HTTP REST API. !!! In the case of control by your own system, the servo drive is not guaranteed. Basic requirements for system operation: - max. air flow through one fully open damper is 100 m3/h. Depending on the position of the damper and the percentage of its closure, the maximum allowed flow rate (LFmax) is reduced proportionally. The air flow rate through one or more distribution boxes (PBmax) generated by the heat recovery unit in one direction (supply/exhaust) must not exceed the sum of the maximum flows of all dampers PBmax < ΣLFmax - air temperature flowing through the damper 10-40°C - air temperature around the actuator and control board 10-40°C, humidity 30-90% RH - it is always necessary to maintain access to the control board and actuators for possible replacement Service To clean the piping system, the damper blade can be easily removed through a conveniently located service opening from the distribution box. To remove the damper axis and the outer part with the actuator, it is necessary to remove two screws using a Phillips screwdriver. The damper body and the neck do not need to be removed.

Price on request

we will make

do 19.02.2026